Tranalysis

The 11th China (Shanghai) International Technology Import and Export Fair (hereinafter referred to as \Shanghai Fair\) will be held at the Shanghai World Expo Exhibition and Convention Center from June 11th to 13th, with a total exhibition area of 35,000 square meters, gathering innovative achievements from nearly 20 countries and regions around the world and 20 provinces and cities across the country, with nearly a thousand participating companies.

On May 28th, reporters from The Paper (www.thepaper.cn) visited Ou Bi Nuo Biotechnology Co., Ltd. in Pudong Zhangjiang and Mi Kai Luo Na (Shanghai) Industrial Intelligence Technology Co., Ltd. in Jinshan Tinglin, to preview the highlight exhibits and technologies that will be showcased at this session of the Shanghai International Trade Fair.

Optical tweezers technology: Manipulating cells at the nano to millimeter scale.

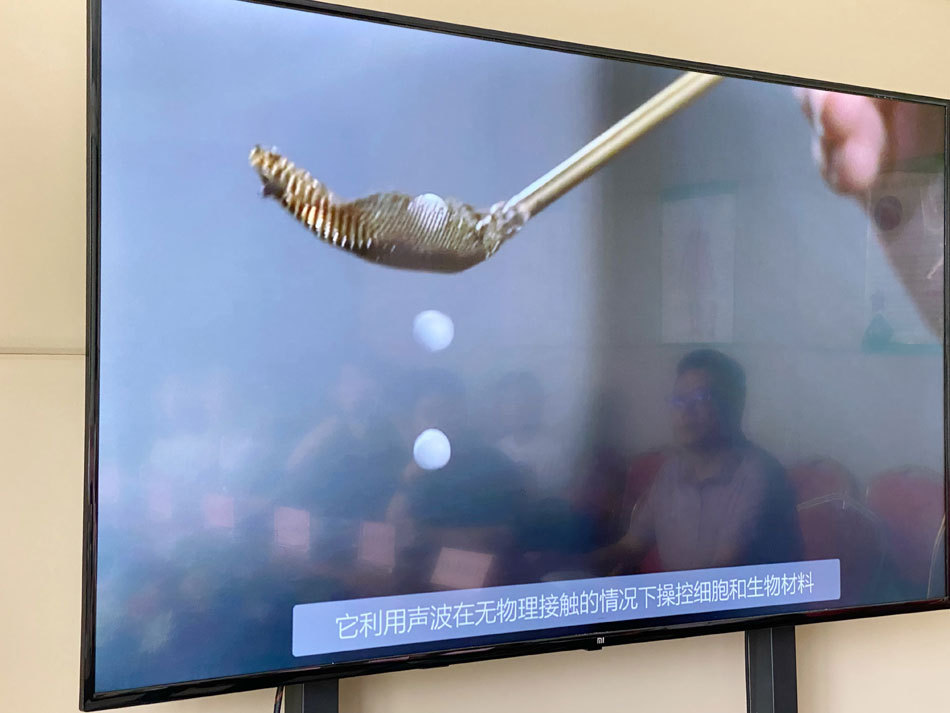

The acoustic tweezers technology, in layman's terms, is the use of sound as tweezers to manipulate cells and biological materials without physical contact using sound waves. All the figures in this article are taken by The Paper's journalist, Yu Kai.

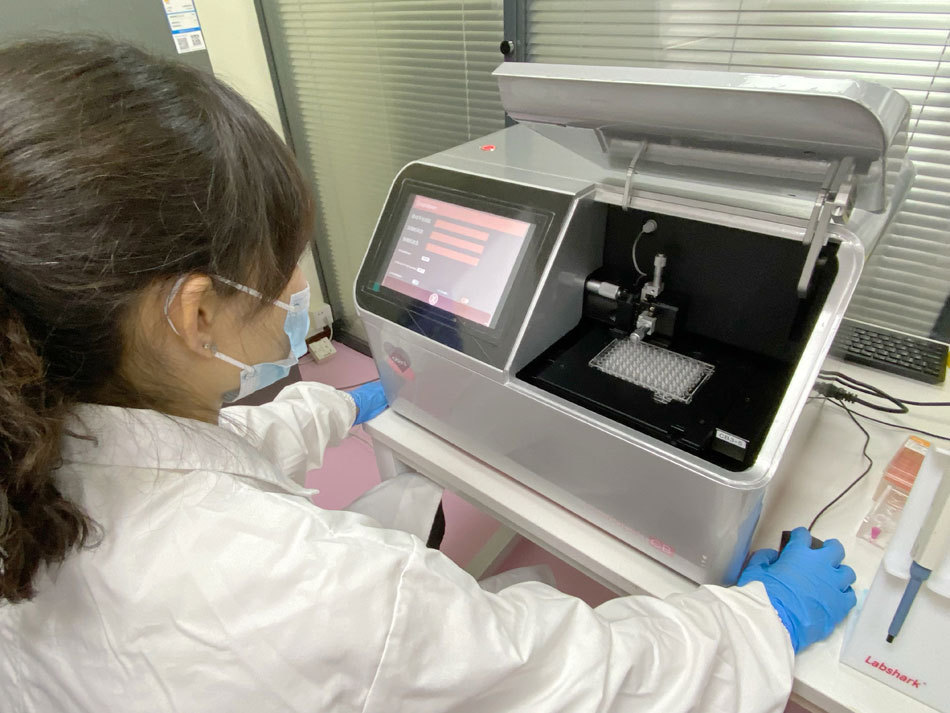

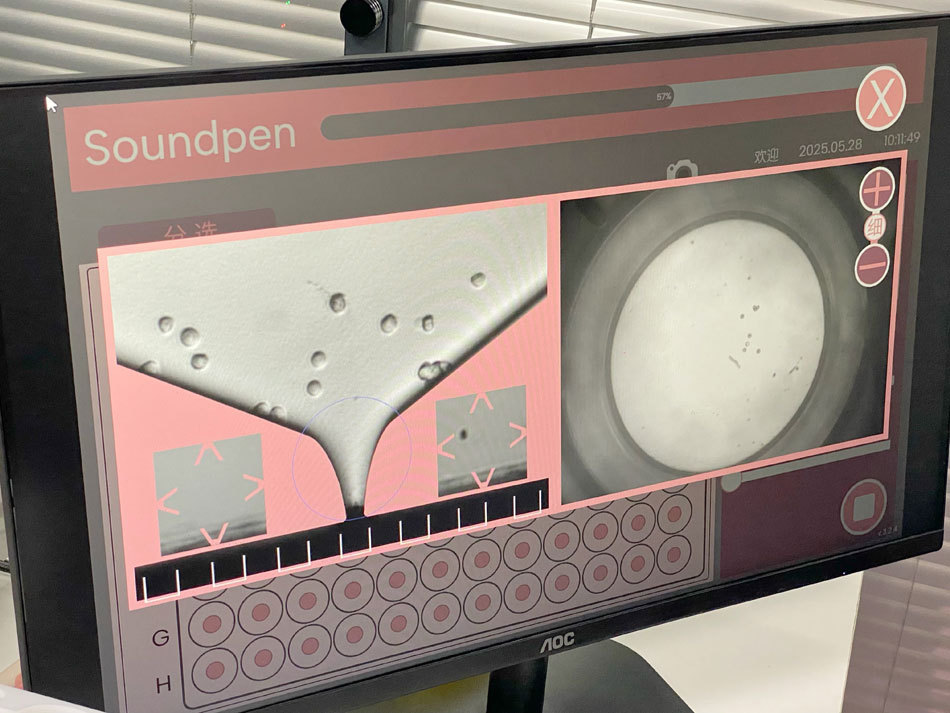

\Acoustic tweezers technology, in layman's terms, is using sound as tweezers to manipulate cells and biological materials without physical contact by utilizing sound waves,\ Zhuang Hui, the marketing manager of Oubino Biotechnology Co., Ltd., told the reporter. As one of the few companies that have industrialized acoustic tweezers technology, the Soundpen CB system developed by Oubino is currently the only device in the world that uses acoustic tweezers technology for single-cell sorting. It adopts a non-contact, label-free acoustic tweezers manipulation method, capable of precisely manipulating cells at scales ranging from nanometers to millimeters. This technology effectively avoids the damage to cells caused by traditional optical tweezers and microfluidics, ensuring cell viability. In terms of application effects, the acoustic tweezers single-cell sorting system has increased the single-cell sorting rate by 5-6 times compared to the traditional limited dilution method.

In terms of technological status, this acoustic tweezers technology not only fills the domestic gap but also surpasses international competitors in aspects such as single-cell printing precision, sample compatibility, and cost control. Currently, similar products on the market mostly rely on imports, while Oubinu's acoustic tweezers technology allows domestic equipment to stand out on the international stage. The company has applied for more than 20 invention patents, covering core technologies such as acoustic manipulation, droplet ejection, and cell enrichment, building a solid barrier of independent intellectual property rights.

Oubino Biotechnology, with its world-leading acoustic tweezers technology, has successfully developed the single-cell sorting system Soundpen CB, which will be displayed at this session of the Shanghai International Technology Fair.

In this session of the Shanghai International Technology Equipment Exhibition, the company will showcase two single-cell sorting systems of different models. The price of one of the devices is around 950,000 yuan, which is nearly 350,000 yuan cheaper than European competitors that use piezoelectric technology for cell sorting.

\ hope that through our debut at the Shanghai International Trade Fair, we can gain recognition from leading biopharmaceutical companies and university research institutes, successfully replacing imported equipment with domestic ones. It is expected that by next year, the monthly production capacity of our Suzhou factory will reach around 50 units,\ said Zhuang Hui. \We believe that the acoustic tweezers technology will play a significant role in applications such as ultracentrifuges, liquid handling stations, exosome enrichment, and organoid printing in the future. It has the potential to unleash tremendous potential in the fields of precision medicine, gene therapy, and regenerative medicine, injecting new vitality into the development of the biopharmaceutical industry.\

Laser welding: The efficiency is several times that of manual welding.

\At this Expo, we will bring the lithium metal cutting and stacking machine protected by a glove box, which is a key process equipment for solid-state batteries, overcoming the difficulties of lithium metal film being easily affected by water and oxygen and the difficulty of cutting and stacking. Mikarona has completed the development of the pilot line for each process of solid-state lithium batteries and will establish a fully automatic solid-state battery pilot line experimental platform in Songshan Lake, Dongguan, by the end of June this year, providing free experiments or process and material verification for researchers nationwide to promote the development of solid-state battery technology.\ Liu Xuefeng, the person in charge of Mikarona Company and the Dean of the Fengyuan Lithium Battery Equipment Research Institute, said that the company has been aiming at the overseas lithium battery industry since 2024, has made progress in countries such as Australia and Russia, completed the delivery of small-scale experimental lines worth tens of millions, and is currently signing contracts for small-scale solid-state lithium battery production lines worth hundreds of millions.

Liu Xuefeng introduced that Mikailuona is a high-tech enterprise integrating R&D, manufacturing, sales, and service, holding a leading position in the fields of vacuum automation and intelligent vacuum equipment. The company's product range covers isolation and protection glove boxes, automated industrial intelligent equipment, etc., widely used in the fields of lithium batteries, nuclear industry, etc., currently holding more than 170 patent technologies, and has passed the \High-tech Enterprise\ and \Specialized, Fine, and Special New\ enterprise certification, and is also a qualified supplier of the China National Nuclear Corporation.

The lithium metal cutting and stacking machine in the exhibition hall of Michelangelo (Shanghai) Industrial Intelligence Technology Co., Ltd.

In the welding area of the Mikailo workshop, workers are using the company's self-developed laser welding process, assisted by robotic arms and vision positioning technology, to perform live operations of vacuum chamber laser welding.

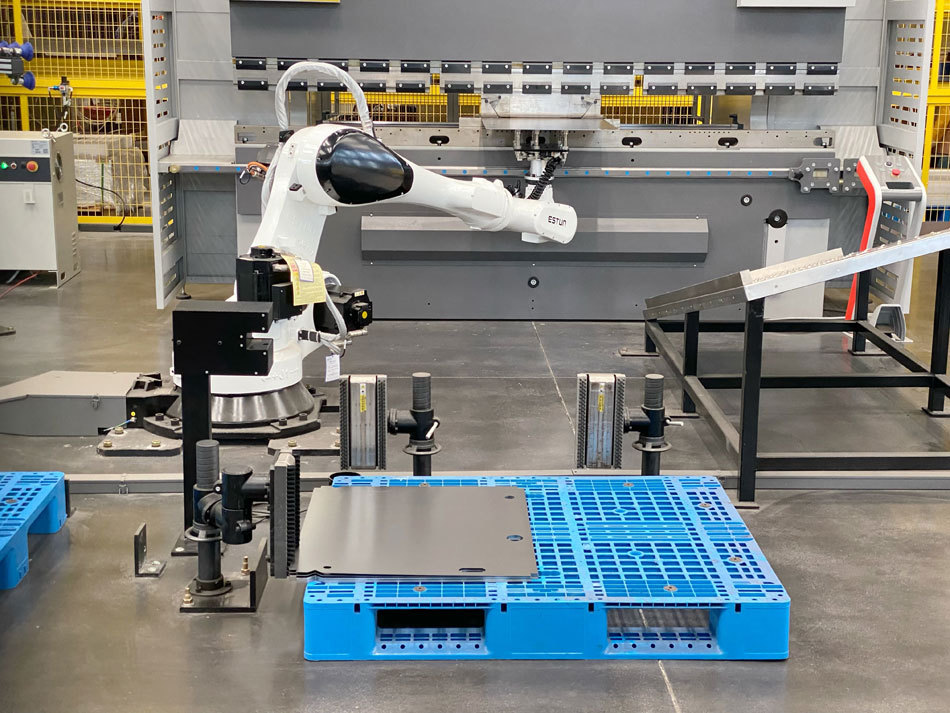

The \automatic bending robot\ is working.

On the same day, reporters at the welding area of the Michelangelo workshop saw workers using the company's self-developed laser welding process, assisted by mechanical arms and visual positioning technology, to perform live operations of vacuum chamber laser welding. Company technician Shao Zhushan told reporters that laser welding has the prominent advantages of fast speed, quick heat dissipation, no deformation, good quality, and high efficiency. It can achieve single-sided welding and double-sided shaping, with an efficiency several times that of manual welding, and can also achieve non-destructive testing. In addition to welding, the company has also achieved AI empowerment in the vacuum chamber component processing link. The \automatic bending robot\ can automatically pick up, bend, and place the metal components of the vacuum chamber based on the drawings input into the computer, with a processing accuracy that can reach the micron level. It is not only highly accurate and fast but also safer.